Custom Precision Parts Manufacturer, Made Fast & Right

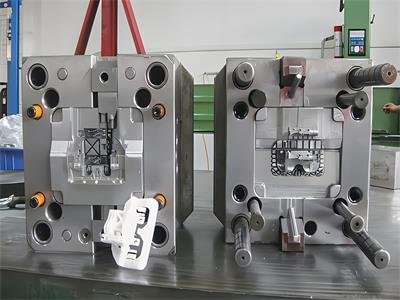

Our manufacturing capabilities

From prototypes to full-scale production, Xu Feng provides end-to-end precision manufacturing services

Solve Your Manufacturing Challenges

Discover how companies like yours have succeeded with XuFeng’s manufacturing solutions.

5-Axis milling for complex aluminum components of robotics

Xu Feng successfully tackled the precision CNC machining of complex aluminum components for a Florida-based robotics company, ensuring a flawless Ra0.6 finish and leak-proof mating surfaces. We achieved repeatable accuracy in high-volume production using advanced 5-axis milling and innovative tooling. Challenge us with your intricate designs for unparalleled machining solutions.

Progressive Die With in-die tapping for Water Heater Component Manufacturing

Our team revolutionized the production of a drawing part for an Argentina water heater manufacturer by processive matrix, combining multiple operations into one and significantly cutting the size of the mold and production times. We achieved precise tolerances and rapid delivery by utilizing an auto feeder and adjusting the strip gap with ending to save the client time and money.

Rapid Prototyping injection mold for the microfluidic board of Medical Device

In 2023, our team swiftly responded to a Canadian firm’s request to prototype microchannel plastic panels. Guided by the client, we initiated production testing with injection molds, incorporating etching technology. We’ve successfully crafted experimental molds, supplied samples. we are currently fine-tuning in preparation for the mass production of both molds and products to meet the massive production.

How to Work With Us

With four simple but effective steps, you can turn your idea into on-demand parts.

Send us your inquiry

To start, contact us and send your design file or pictures of part.

Get a Quote with DFM

Within a few hours we'll send you design for manufacturability (DFM) analysis and real-time pricing.

Start Manufacturing

Once you review your quote and place the order, we'll start the manufacturing process. We also offer finishing and assembly options.

Parts are shipped

After passing QC inspections, parts are well packed for delivery. Quality guarantee for every part.

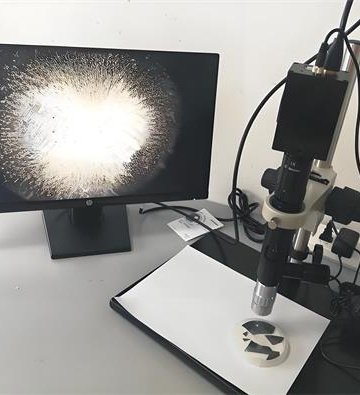

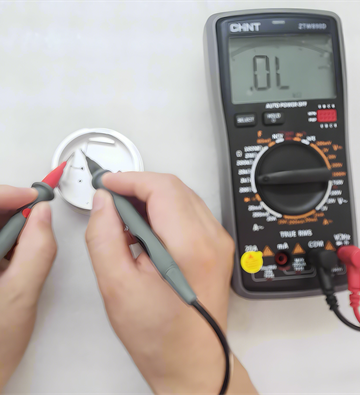

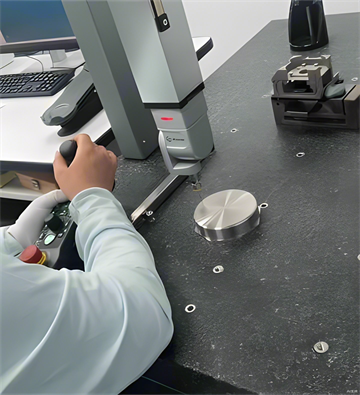

Quality Management of Products

Your satisfaction is our top priority. At Xu Feng, we have developed a set of rigid processes to ensure the ISO manufacturing standard is applied to every custom part.

Surface Inpection

Dimensions Inpection

Hardness Testing

Roughness Insepction

Flim thickness testing

Insulation testing

Geometric Tolerances

Assembly testing

Your Solution for Sourcing and Manufacturing Challenges

Free DFM and samples for tooling trial, quick-turnaround process to save your money and time.

Between our factories and network of partners, you never have to worry about our capacity.

Engineering team provide answers to all your manufacturing inquiries during and after the production.

Why Clients Choose Us as a Long-Term Supplier

Xu Feng has developed a set of rigid processes to ensure the ISO manufacturing standard is applied to every custom part. Every step is open and transparent to our customers, and we hold integrity as our highest value.

Xu Feng can help turn your concerns to the part with proactive and professional support 24/7.

We follow a strict QC system to ensure the quality from prototypes to production parts manufactured.

If the parts fail to meet your specifications, contact us and we will deal with your problem within 1-3 business days.

The suitable packing material used for the small and heavy parts, at the same time, the assurance combined during the shipment.

See What Our Customers Say About Us

Testimonial

Work With Numerous Industries

With a wide selection of production-grade metal and plastic materials, Xu Feng can assist clients with on-demand parts across various industries.

Xu Feng helps medical device manufacturers, tech support companies, and research labs from prototyping solutions to mass production.

-

- New product development- prototyping solutions

- ISO 13485:2016 certified

- Right Materials for Medical Product Development

-

- New product development- prototyping solutions within 2-3 days

- Precision parts with a tolerance down to ±0.001 in. (0.020mm)

- A range of materials for product development

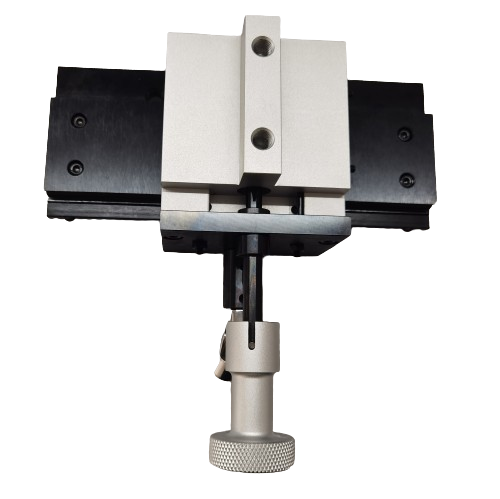

Whether you’re developing unique clamps, customized fixtures or workholdings, or an entirely new auto system with a large number of custom components, Xu Feng provides the capacity for making such customized parts.

Small and medium size custom parts with varying levels of complexity

3D and 2D drawings created from your original samples or hand-drawing

Surface treatment and assembly solutions

Xu Feng has rich experience working with OEM and aftermarket automotive companies to make parts for prototyping of new components, replacement parts, and accessories.

- Complex geometries & tight tolerances to ±0.0004″ (0.01mm)

- Make quick turn prototypes and production parts in days

- Huge selection of durable & resistant materials as well as a wide range of surface treatment

At Xu Feng, we specialize in propelling your product development forward. From electronic devices to kitchen appliances, and audio systems to tools and outdoor equipment, our expertise ensures your innovations reach the market faster.

- Competitive pricing, Intellectual property protection and DFM guidance

- Customization at any scale, Whether it’s a prototype or production

- To your spec and on time, every part and every time

By focusing on meeting the unique demands of the energy sector, Xu Feng help companys in energy field to accelerate the development of the custom components, whether it’s the parts for new energy systems or accessories for traditional energy equipments.

- Superior-quality energy component trusted by Toyota etc.

- 24/7 engineering support during your parts manufcturing

- Build an agile supply chain through its industry-leading on-demand manufacturing