Get an instant quote for your on-demand parts with our CNC machining services. Choose from 40+ materials and 10+ surface finishes. Whether for rapid prototypes or production parts.

Our CNC Machining Services

Transform your designs with our precision CNC milling, from basic 3-axis to complex 5-axis projects

Utilize our on-demand CNC turning for reliable, custom metal and plastic parts tailored to your projects

Enhance mold tools with our EDM and Grinding services for precision holes, pockets, and textures in hardened steel

Our Precision Machining Tolerance

| Metal | Plastic | |

|---|---|---|

| Maximum Part Size | 1450*750 mm | 1450*750 mm |

| Minimum Part Size | 10*10 mm | 10*10 mm |

| Min Wall Thickness | 0.2 mm | 0.2 mm |

| Min Hole Size | 0.5 mm | 0.3 mm |

| Tolerance | ±0.02 | ±0.05 |

| Roughness | Ra1.6 | Ra3.2 |

| Metal | Plastic | |

|---|---|---|

| Maximum Part Size | Φ550 * 950 mm | Φ550 * 950 m |

| Minimum Part Size | Φ0.8 *1 mm | Φ1 * 1 mm |

| Min Wall Thickness | 0.5 mm | 0.2 mm |

| Min Hole Size | 0.5 mm | 0.6 mm |

| Tolerance | ±0.01 | ±0.02 |

| Roughness | Ra0.8 | Ra1.6 |

* The table provided general guidelines, please inquire about anything larger or smaller. Tight tolerances can be required depending on the process, material choice, or part geometry.

CNC machining materials

Xu Feng offers instant quotes on a diverse array of over 40+ commercial-grade metals and plastics, including speciality materials like wood and carbon fiber plates, tailored for specific applications.

Xu Feng has extensive experience in machining aluminum alloy parts with various surface treatments. 30% of our CNC machining products are made from it.

Al 6061 -T6/T651

Al 7075-T6/T8

Al 6262-T8

Al 5052

Al 2024

Aluminum alloys are a popular choice for machining due to their low density, good mechanical properties, high thermal and electrical conductivity, and resistance to corrosion. It is widely used in different fields and cost-saving in shipment.

Compared to aluminum alloy, stainless steel is less CNC-friendly due to the high cutting forces and temperatures required, leading to adhesion, welding, and tool sticking.

However, its durability, strength, and corrosion resistance make stainless steel the preferred choice for many projects. Xu Feng specializes in developing stainless steel components for a variety of applications, including bioreactors, diving equipment, medical devices, and transmission systems.

SS316/SS316L

SS304/SS304L

SS303

Carbon steel is a commonly used due to its cost-effectiveness, good machinability, high strength, and versatile heat treatment methods. However, it often requires surface treatment to prevent rusting, At Xu Feng, we offer various surface treatments to address this need.

Steel 1020

Steel 1045

Q235

Alloy steel refers to steel that has been enhanced by adding various alloying elements to the base of carbon steel, such Mn, Mo, Ti, Gr, Ni. etc. These additions improve the steel’s properties, making it suitable for more demanding applications. At Xu Feng, we provide high-quality alloy steel components tailored to meet your specific requirements.

When we refer to copper, we typically mean red copper. Known for its excellent thermal and electrical conductivity, At Xu Feng, copper is widely used in electronics. In the EDM process, copper electrodes are machined for precision applications.

Copper’s good cutting performance and machinability make it ideal for mechanical processing. It is commonly used in the production of bearings, gears, and pressure sensors.

C10100

C12200

CuCrZr

Brass is an alloying consisting of both copper and zinc. comparable to mild steel, brass ensures durable and reliable character. At Xu Feng, we specialize in producing connectors and various components from brass, leveraging its excellent machinability. To prevent oxidation, we provide surface treatments or package parts in a vacuum for shipment, ensuring the highest quality for your products.

H62/H68

HPb59-1

HSn70-1/HSn62-1

Additionally, brass’s distinctive golden color, soft luster, and smooth surface make it a popular material for crafting fine handicrafts.

Usually, bronze used for the casting, it was used very early in the history of China.

But bronze noted for its toughness and resistance to wear, is an excellent choice for machinining, producing intricate components used in a variety of industries, including electrical connectors, bearings, and gears.

C90300/C86300/C83600

C64200/C63000/C61400

And some clients choose it for the application of housing hold, such as the handle of door and drawer which to show the sense of history, of course, Xu Feng also offers various surface treatments to meet your specific requirements.

Due to its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. Titanium is a popular material for the machining of components for medical devices, aerospace, automotive, industrial equipment and energy sector.

TC4 (Gr5)

TA2 (Gr2)

However, titanium presents unique challenges in machining due to its high strength, low thermal conductivity, and tendency to work harden during cutting.

At Xu Feng, we provide specialized CNC machining services for titanium components, such as connectors for diving equipment, tools for medical devices, and intricate artwork.

Tungsten alloy stands out due to its exceptional density and hardness, making it ideal for high-wear applications. This heavy metal alloy is especially valued in industries that demand materials capable of withstanding extreme conditions, such as aerospace, defense, and medical equipment manufacturing.

Similar to titanium, tungsten alloy is challenging to machine. At Xu Feng, we utilize specialized cutters and cooling fluids designed specifically for machining this material. Our experienced engineers optimize key parameters—cutting speed, feed rate, and depth of cut—to efficiently and precisely machine tungsten carbide products.

YG20C

93WNiFe

ABS is a favored plastic material for CNC machining due to its high impact resistance, good machinability, and excellent dimensional stability.

At Xu Feng, we assist clients with both prototyping and small-scale production using CNC machining. ABS is widely utilized for structural components across various industries, including automotive, consumer goods, medical, and electronics.

Off-white

Black

Red

Blue

Delrin, a type of POM, is a popular material for CNC machining due to its high strength, low friction, and excellent dimensional stability.

At Xu Feng, we assist our clients each year with CNC machining for a variety of Delrin parts, including gears, connectors, plates, and small tubes. Delrin is an ideal choice for precision parts in mechanical and automotive applications, offering tolerances of ±0.03 mm under constant temperature.

Black

White

Off-White

Compared to ABS and POM, PEEK is more expensive, which limits its use in some low-cost applications. However, it is a highly sought-after material for CNC machining due to its exceptional mechanical properties. PEEK offers an excellent strength-to-weight ratio, high chemical resistance, and superior thermal stability.

At Xu Feng, we recommend PEEK for components that demand high performance under extreme conditions. It is extensively used in the aerospace, medical, and automotive industries.

Ceramic white

Yellowish brown

Black

Nylon is another popular material for CNC machining due to its high strength, excellent wear resistance, and good impact resistance. These properties make it suitable for a wide range of applications, including gears, bushings, and insulating components.

However, machining thin-walled nylon parts can be challenging due to the potential for deformation and difficulty in controlling accuracy. Clamping and cutter selection are crucial factors that affect the outcome. Xu Feng has extensive experience in machining such components, ensuring precision and quality.

Black

White/Transparent

Blue/Red

When PVC is used for CNC machining, achieving a smooth surface can be challenging, and the material’s weak toughness makes it prone to breaking. At Xu Feng, we have the expertise to address these issues effectively.

Despite these challenges, PVC is highly valued for its chemical resistance, good insulation properties, and excellent durability. These characteristics make it ideal for applications such as electrical housings, piping, and medical devices. Its lightweight nature and resistance to corrosion and chemicals make PVC a versatile choice for various industrial applications.

Off- white

Grey

Black

Xu Feng has developed numerous polycarbonate (PC) parts tailored to meet the unique requirements of our clients. PC is a preferred material for many components due to its exceptional impact strength, transparency, and inherent flame retardancy.

Its excellent dimensional stability and superior electrical insulation properties make PC ideal for applications in the automotive, household, and electronics industries.

Transparent

White

Black

Polyethylene (PE) has a low melting point, so it’s crucial to manage heat build-up during machining to prevent deformation or melting. Using sharp tools and appropriate cutting speeds is essential. At Xu Feng, our skilled engineers handle this process expertly.

Known for its lightweight properties, chemical resistance, and high impact strength, PE is a favored material for CNC machining components, especially in environments where moisture resistance and electrical insulation are necessary. It is an ideal material for consumer goods, containers, and piping systems.

White

Green

Black

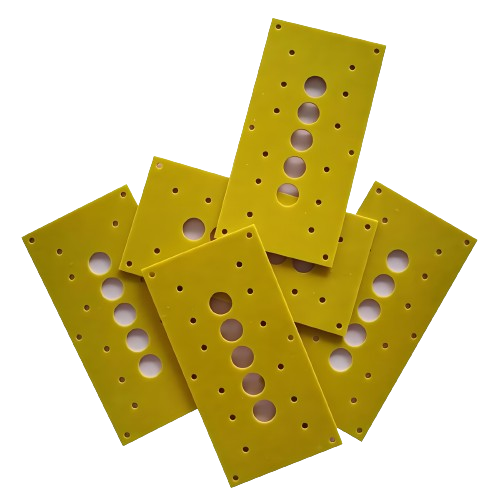

FR-4, a composite material made from woven fiberglass cloth with an epoxy resin binder, is commonly used for printed circuit boards (PCBs) due to its excellent electrical insulation properties, flame resistance, and mechanical strength.

During machining, fine fiberglass dust is generated, which can be hazardous to both health and equipment. At Xu Feng, we are equipped with effective dust extraction systems to manage this issue efficiently, ensuring a safe and clean working environment.

Aquamarine

Yellow

Black

Polybutylene Terephthalate (PBT) is valued for its high strength, rigidity, dimensional stability, and resistance to solvents and chemicals. However, its relatively low melting point necessitates careful control of machining temperatures to prevent deformation.

At Xu Feng, we specialize in machining PBT to achieve high-quality surface finishes using precise tools and parameters. By fine-tuning feed rates and speeds, we ensure optimal results for your components. Our expertise extends to producing diving equipment parts from PBT material, achieving surface finishes as smooth as Ra0.8.

Black

White

Teflon, the well-known brand name for Polytetrafluoroethylene (PTFE), is prized for its non-stick properties, chemical resistance, and thermal stability. These features make it ideal for the chemical, automotive, and food processing industries.

PTFE’s high coefficient of thermal expansion can cause deformation and affect machining accuracy. At Xu Feng, our expert engineers skillfully manage these challenges to ensure precision and quality in every PTFE component.

White

Black

PPSU (Polyphenylsulfone) is renowned for its exceptional thermal stability, high mechanical strength, and outstanding chemical resistance. These properties make it an ideal choice for demanding applications in the food, medical, aerospace, and automotive industries.

PPSU’s high heat resistance and durability can present challenges during machining, such as tool wear and maintaining tight tolerances, and it is hygroscopic, so it must be thoroughly dried before machining.

At Xu Feng, our experienced engineers adeptly handle these complexities, ensuring precision and quality in every PPSU component.

Tawny

Off-White

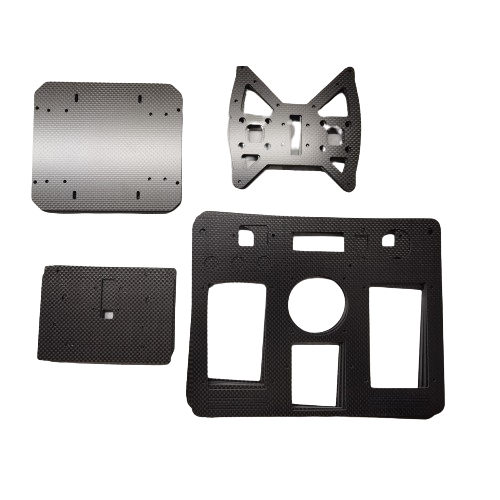

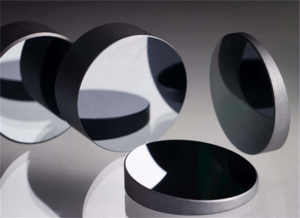

In addition to our expertise in metal and plastic components, XuFeng offers precision machining services for a variety of special materials, including carbon fiber and wood.

Carbon Fiber: Ideal for high-strength, lightweight applications in agriculture, automotive, and consumer products.

Wood: We specialize in producing MDF parts, such as gaskets for medical equipment, ensuring quality and precision.

If your project requires unique or unconventional materials machining, don’t hesitate to reach out. Our skilled engineering team is ready to provide tailored solutions to meet your specific requirements.

* For materials not shown here, please get in touch with us directly

Finishing Options for CNC Machining

| Surface Finishing | Description | Applicable Materials | Color | Texture | |

|---|---|---|---|---|---|

| As machined | No requirement from client, characterized by roughness 3.2μm, with tool marks, but without burrs. | All material | n/a | Stain |

| polishing | Enhances the surface by removing imperfections, smoothing it, and creating a shiny, reflective and smooth appearance, with Ra0.8~Ra0.1. | All material | n/a | Golssy, Smooth, Shining |

| Brushing | Uses abrasive brushes or belts to create uniform linear or textured patterns on material's surface, enhancing its appearance and texture | Metal material | n/a | Stain |

| Passivation | Removes surface contaimnants and forms a protective layer on metal surfaces, preventing corrosion and improving resistance to enviromental degradation | Stainless Steel, Brass, Aluminum | Clear, Sliver | Matte |

| Marking | A processs of adding permanent, visible or coded information onto a surface using methods like engraving, laser ething, silk-screen pring or stamping for identification, branding or tracking purposes. | All material | Custom | n/a |

| Anodizing | An electrochechmical process that forms a protective oxide layer on aluminum parts, enhancing corrosion resistance and allowing for different colored finishes, while mantaining a porous texture. | Aluminum | Clear, Red, Black, Grey, Brown, Yellow, Gold, Blue | Stain, Matte |

| Electroplating | A metal coating is applied onto a substrate using an electrolytic process, impoving aethetics, corrosion resistance and wear resistance. | Steel, Stainless steel, Aluminum | Gold, Silver, Nickel, Copper, Chromate, Galvanize | Golssy, Smooth |

| Powder coating | finely ground particles of pigment and resin are electrostatically sprayed onto a surface, then baked to create a durable, smooth, and colorful finish on metal part. | Metal material | Black, White, Gold, Blue | Matte |

| Blacking | Create a black, corrosiion-resistant layer involves chemically altering the surface of steel or stainless steel, often used for decorative or protective purposes. | Steel, Stainless Steel | Black | Stain, Matte |

| Blasting | Uses abrasive materials, like sand or grit, propelled at high velocity to remove contaminants, texture surfaces, or prepare them for futher treatments. | Aluminum, Brass, Copper, Steel, Stainless Steel | Matte | n/a |

*Additional finishing options include chromic acid anodizing, Teflon plating, gold plating, silver plating, and more. For the finish not listed here, please inquiry us directly.

CNC Machining Solutions For Our Customers

Xu Feng supports our customers from initial prototyping to low-volume production for market development, and on-demand manufacturing to meet your specific market needs.

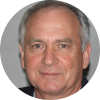

01. Rapid Prototyping

CNC machining is one advantageous way to turn our drawings into a true product.

“The difference with Xu Feng offers is that fast turnaround time, I get my parts as fast as one week to ensure my product meets the tight market requirement.”

Rafal Kowolik

Vice President

Medical Devices

02. Low-Volume

Low-volume production is essential during the market development phase.

“Xu Feng gave the same level of attention and priority to my small orders and operated with the right competitive cost, I am very happy with the quality.”

Mr. Anita

Director of Operations

Supplier Source

03. High-Volume

Xu Feng supports every client with on-demand production to meet their market requirements

“At Xu Feng, we ensured 10% cost savings to the local suppliers, but the capacity to build my product and get it to me in a very rapid cycle time”

Samuel Hewitt

Project Manager

Rehabilitation robot

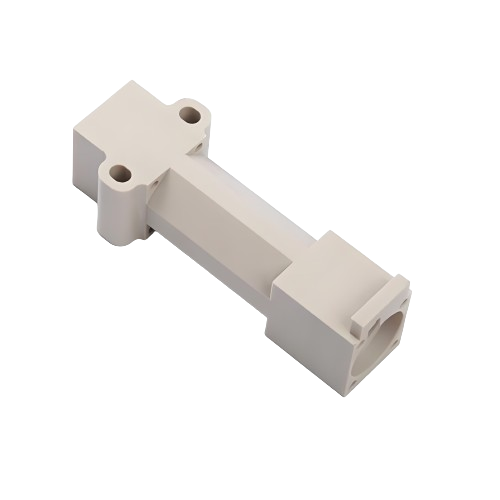

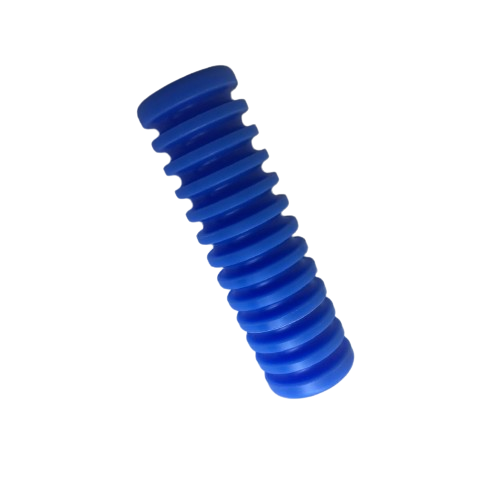

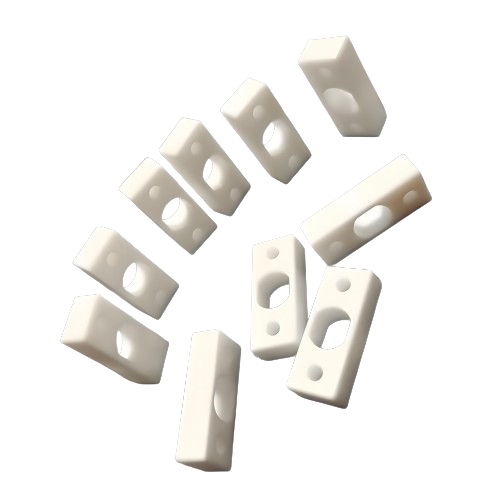

CNC Machined Parts Made by Xu Feng

Here are some custom CNC machined prototypes and end-use parts we’ve produced for our customers

FAQs For CNC Machining Service

How much does CNC machining cost?

The best way to find out the cost is to submit your design drawings and get an instant quote from us. The price varies based on materials, geometry, quantity, and lead time.

We can start from around $200. our CNC machining services are competitively priced between $30 and $50 per hour, and your purchasing quantities can be as low as 1 to 200 parts from a prototype to low volume.

How to reduce CNC machining costs?

The best way is to work with the right manufacturing team. I think you will agree with me that “why should I choose to work with you” is not because of how good we are or how cheap our offer is. It’s because our offer meets your needs, and our product can achieve your desired result and performance.

Our professional team is dedicated to offering more than just manufacturing solutions. We provide valuable insights that can enhance your product’s design and functionality—advising on design simplifications, material selections, and manufacturing practices that avoid unnecessary complexities like thin walls or stringent tolerances, tailored specifically to your application’s needs.

What materials can you machine?

Our instant quoted materials can be found in the table, for most metal and plastic bars, sheets or tubes. and you can always request a custom material even special materials such as rubber, wood, carbon fibre, industrial ceramics, hard metal alloy etc.

What tolerances can your CNC machines achieve?

We adopt standardized tolerances ISO 2768 -mK without special requirements. For even more precise requirements, our advanced CNC machines can achieve tolerances as tight as ±0.0002 inches (±0.005 mm). The achievable tolerance depends on several factors including the material, part geometry, size, and the specific type of CNC machine used, you can contact our experts for the details.

What is your typical lead time for CNC machining orders?

Lead times for CNC machining orders can vary based on several factors, such as the complexity of the parts, the volume of the order, the type of materials used, and the current workload at the manufacturing facility. Here’s a general lead time we work for you.

- Prototyping: 5-7 days, for simple prototypes, lead times can be as short as 1-3 days.

- Low-volume: 1-2 weeks, from a few dozen to several hundred parts.

- Large-volume: 3-4 weeks or more, especially when involving complex parts or multiple setups, lead times can be extended.

How do you ensure quality control?

1. Material Inspection

Prior to machining, we conduct thorough inspections of all materials. This includes obtaining Material Data Sheets from our suppliers and ensuring all materials meet the required specifications, such as correct dimensions, composition, and freedom from defects.

2. In-Process Quality Checks

Our machining programs are meticulously reviewed by a program engineer, and we conduct a first-part inspection to set benchmarks. Our machines are equipped with probes to monitor position and size accurately, while force and vibration sensors mounted on the machines or tools continually assess the machining conditions. This enables us to replace any worn-out tools promptly, maintaining the high quality of parts.

3. Advanced Measurement Tools

- Coordinate Measuring Machine (CMM): We employ CMMs for complex and high-precision parts to ensure all dimensions, tolerances, and geometries meet your stringent requirements.

- Optical Inspection: For smaller, detailed components, our optical inspection systems offer non-contact measurements, detecting even the smallest discrepancies.

4. Final Quality Assurance

After machining, each part undergoes a comprehensive final inspection to confirm that every dimension and specification is adhered to. This process includes visual inspections and functional testing, with all results meticulously documented to meet your requirements.

5. Feedback and Improvement

We actively seek and value feedback from every client on each project, as it is crucial for our continuous improvement. Your feedback not only helps us identify areas for enhancement but also strengthens our long-term cooperation, ensuring mutual growth and success.

Can you assist with design modifications?

Before your project moves into production, our experts will review your design drawings and provide actionable recommendations to enhance manufacturability, free Design for Manufacturability (DFM) feedback service is provided. Our engineering team is ready to assist in refining your designs to ensure optimal production outcomes if modifications are necessary. Even if you only have samples, we can help by creating the necessary drawings.

How do you ensure the confidentiality and security of our designs and intellectual property?

We know how critical information security is, especially when working with new designs. That’s why we advise you to send us your drawings by email system thought the official email address. and if you need extra assurance. We’re happy to sign an NDA.

Turn Your Idea Into True, Faster