- Instant Pricing in one day

- Parts as Fast as 3 days

- Tight Tolerances to ± 0.01 (.0004'')

Table of Contents

We use CNC lathes with live tooling to create precise, complex features like axial and radial holes, flats, grooves, and slots. Prototypes can be made as fast as 1 day for both metal and plastic parts with tight tolerance.

Our CNC turning service is commonly used for:

- Parts with circular or cylindrical shapes

- Functional prototypes and end-use parts

- Parts with holes, flats, grooves, and slots for mechanical and assembly purposes

Precision Turning Tolerance

| Metal | Plastic | |

|---|---|---|

| Maximum Part Size | Φ550 * 950 mm | Φ550 * 950 m |

| Minimum Part Size | Φ0.8 *1 mm | Φ1 * 1 mm |

| Min Wall Thickness | 0.5 mm | 0.2 mm |

| Min Hole Size | 0.5 mm | 0.6 mm |

| Tolerance | ±0.01 | ±0.02 |

| Roughness | Ra0.8 | Ra1.6 |

* The table provided general guidelines, please inquire about anything larger or smaller. Tight tolerances can be required depending on the process, material choice, or part geometry.

CNC Milling Materials

Alloy and carbon steel are particularly useful for creating fixtures, mounting plates, axles, gears, bolts, studs, shafts, and structural components. durability.

Stainless Steel is widely used in industries such as construction, automotive, aerospace and medical equipment known for its exceptional strength, and durability.

Tool Steel is extremely wear-resistant and tough. It is commonly used to make tools, fixtures, tool holders, punches and gauges.

Brass is a versatile material for various industries. Common applications include gears, lock components, pipe fittings, and decorative parts. It has good electrical conductivity, making it an ideal choice for electrical components

Titanium is lightweight, strong, biocompatible, and highly resistant to corrosion. It is commonly used in industries such as aerospace and medical devices.

Delrin (acetal) is a plastic with low friction and high stiffness. It’s good for machine accuracy, making it an ideal choice for applications where precision is critical. It is commonly used in automotive, aerospace, and consumer goods.

PEEK is a thermoplastic widely used in industries, it has high strength, stiffness, toughness, chemical, biocompatibility, and thermal resistance. Common applications include aircraft structures, electronic components and medical and dental components.

Mill Lead Time:

As fast as 3 days

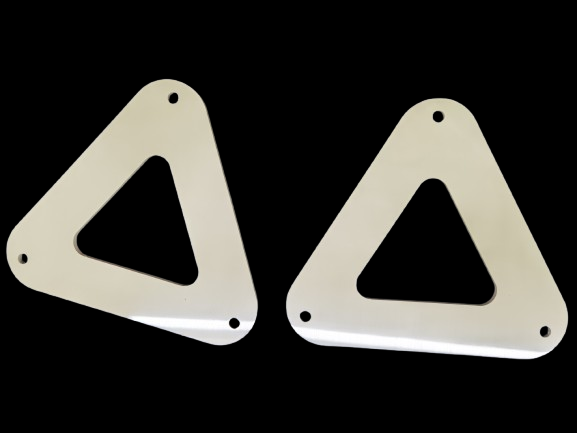

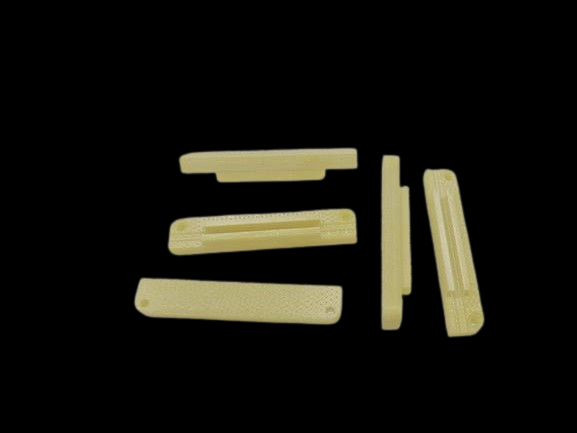

Ceramic white, Yellowish

ABS plastic is widely used in the automotive and consumer electronics industries due to its excellent mechanical properties and ease of processing. Additionally, it can be easily modified with other additives to enhance specific properties such as flame retardancy or UV resistance.

Mill Lead Time:

As fast as 3 days

Off-white, Black, Red, Blue

Nylon is commonly used in engineering and manufacturing processes, including gears, bushing and bearings. Its standout applications include medical devices and electronics insulation, notably screws and spacers for panel-mounted circuit boards.

Mill Lead Time:

As fast as 3 days

White, Black, Blue, Transparent

PC is one of the most commonly utilized plastics in manufacturing, common applications include electrical enclosures, protective shields, connectors, and insulators due to its durable and transparent thermoplastic with good electrical insulation, resistance and flame retardancy.

Mill Lead Time:

As fast as 3 days

White, Black, Transparent

Polypropylene (PP)has a high melting point, excellent chemical resistance, durability, reliability, moisture resistance, high strength-to-weight ratio, and fatigue strength. PP is ideally suited for a myriad of applications—from laboratory equipment and medical devices to consumer goods and aircraft interiors. Its versatility extends to industrial uses such as automotive components, including bumpers, fuel tanks, and battery cases, as well as food processing equipment and ducting systems.

Mill Lead Time:

As fast as 3 days

White (semi-clear or opaque)

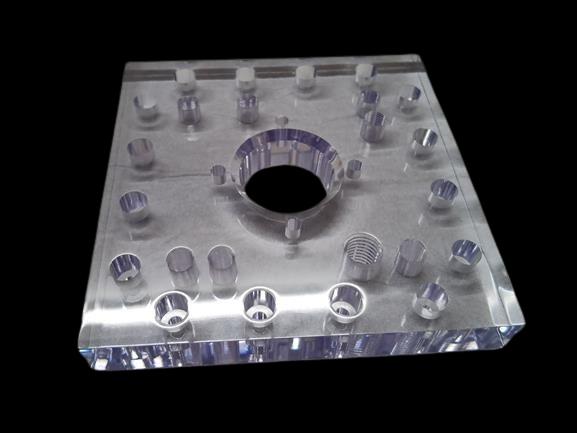

PMMA is a durable plastic that resists scratching and is lighter than glass, making it a popular alternative. Known for its clarity and transparency, PMMA is an excellent option for applications requiring optimal optical performance. It is ideally suited for various uses, including tanks, panels, and optical displays.

Mill Lead Time:

As fast as 3 days

Optically clear, opaque

PMMA is a durable plastic that resists scratching but is lighter than glass which makes it a popular alternative to glass. It is known for its clarity and transparency, making it a great option for applications where optical performance is important, it’s an ideal choice for various applications such as tanks, panels, and optical displays

Mill Lead Time:

As fast as 3 days

Yellow, Black, Aquamarine

*The materials listed here are commonly used in our CNC milling processes. For materials not shown here, please contact us directly.