From Design to Delivery, Xu Feng makes your custom molds and molding parts fast and right to your specs. 30+ materials available and prototyping as fast as 1 day

01.

Rapid quotes in 24 hours

02.

Free DFM feedback

03.

T1 samples in 2 weeks

04

No MOQ

Converting Ideas Into Reality

At Xu Feng, we help you from the idea to 3D drawing in one day, and from sketch to final product in 2-3 weeks.

Injection Molding Options

There are three unique offers for you to choose according to your product lifecycle. Prototype injection molding helps you in development cycles and bridges to production with injection-molded parts within days, while the on-demand process is designed to meet your production needs when your part is put on the market.

| Prototyping | On-Demand Manufacturing | Production | |

|---|---|---|---|

| When | Early Design Stage Low Volume Requirements Testing Materials and Designs | Market Testing and Small Batches Bridge to Production Cost Efficiency at Moderate Volumes | High Volume Production Long-term Use |

| Characteristics | Lower Cost Shorter Lifespan | Moderate Cost Flexibility | High Cost Durability |

| DFM report | ✔ | ✔ | ✔ |

| Mold Flow Analysis | ✔ | ✔ | ✔ |

| Standard Finishes (SPI A1-D3 and VDI) | ✔ | ✔ | ✔ |

| Custom Mold Textures | ✔ | ✔ | ✔ |

| Automatic Lifters and Slides | ✔ | ✔ | ✔ |

| Standard Gating | ✔ | ✔ | ✔ |

| Hot Runner | ✔ | ✔ | |

| Sequential Valve Gating | ✔ | ✔ | |

| Class 104 and 105 Molds | ✔ | ||

| Class 102 and 103 Molds | ✔ | ✔ | |

| Mold Cavity | Single | Single and multi-cavity | Single and multi-cavity |

| Max. Mold Size | 600X600X500 | 600X600X500 | 600X600X500 |

| Machine Tons | 60-400 Tons | 100-400 Tons | 100-400 Tons |

| Lifespan | <2,000 shots | 1-100,000 shots | 1-500,000 shots |

| T1 Speed | 2-3 weeks | 3-4 weeks | 3-6 weeks |

| Tooling Cost | $ | $$ | $$$ |

| Per Unit Part Cost | $$$ | $$ | $ |

Prototype Injection Molding

T1 samples as fast as 1 week

Specification parts are done fast, per your design, and to print tolerances.

Ease of the manufacturing process

Our experts support from design to molding and engineering modification.

More Parts Can Be Provided

After completing prototyping, your tooling can be used to make thousands more parts! We’ll validate your tooling and provide bridge production to meet your growing demands.

Production Injection Molding

Cost Optimization and Scalability

Leveraging our expertise in mold design and efficient manufacturing practices,we partner with you to streamline production costs without compromising quality.

Material Customization

With supporting a wide range of materials, our team guides you in selecting the optimal materials to meet functional and cost objectives.

Precision and Quality Assurance

Achieve exceptional accuracy with advanced CNC tooling and strict quality controls including DFM reports, TPR Tooling Process, and free tooling trail sample confirmation to deliver stable, defect-free parts for every industry.

Injection molding capabilities

Make the move from prototyping to on-demand manufacturing for affordable, high-quality molded parts within days.

Melts plastic and injects it into a mold to form durable, high-volume parts and products.

Pre-made parts are encased in plastic through injection molding to create a single component.

One material is overlaid onto a second substrate part to combine multiple plastic parts into a single component.

Injection Molding Materials

We offer a wide selection of more than 30 thermoplastic and thermoset materials, each selected for its performance characteristics and suitability for different applications.

- ABS

- PC (Polycarbonate)

- PP (Polypropylene)

- PVC

- HDPE

- U-POM

- H-POM/Delrin

- PEEK

- Nylon

- TPE

- PMMA

- PBT

- PET

- PETG

- Tritan

- COC

- TPU

- PS

- LCP

- PPS

- ASA

- PPA

- PU

- PSU

- PVDF

- PPE/PS

- PET/GF

- ABS/GF

- Nylon/GF

- PET/PC

- ABS/PC

- Standard silicone (30, 40, 50, 60, and 70 durometers)

- Medical-grade silicone

- Optical-grade silicone

- Fluorosilicone (fuel and oil resistant)

- Standard rubber

Injection Molding Finishing Options

Mold Texturing

Apply industry-standard textures to a mold by chemical etching or EDM( Electrical Discharge Machining).

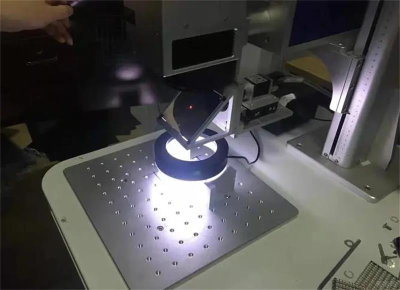

Laser Engraving

Apply to mold for information such as Logos, Cavity ID, Date Code or part numbers, etc.

Silk Screen print

Transfer a two-dimensional image, such as a company logo onto part.

Metal insert

A metal insert, such as a helicoil in standard UNF or metric size, can be installed during injection.

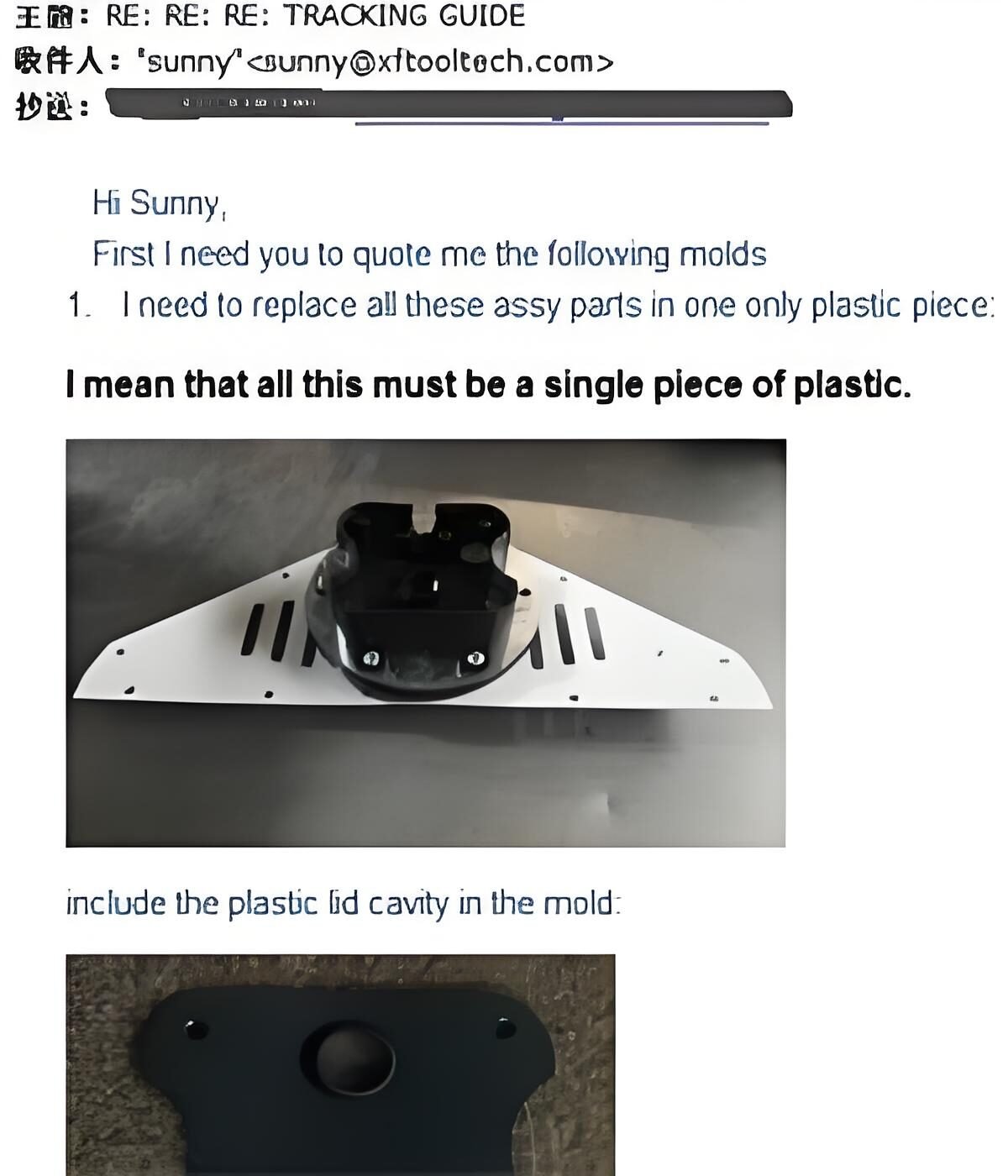

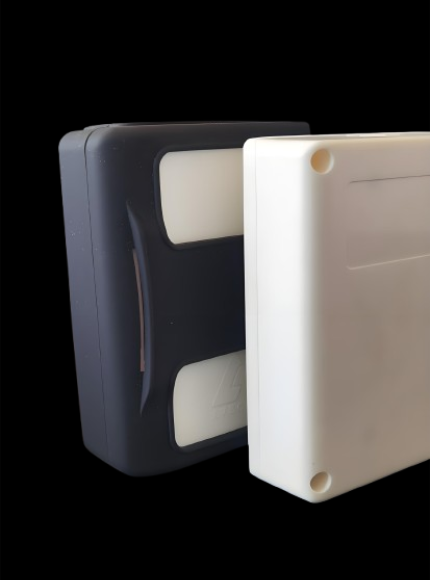

Checkout Our Case

Industry

Medical Devices

Product

Plastic housing

Capabilities Leveraged

Injection Molding

Insert Molding

3D printing

Ultrasonic Welding

Screen Printing

Challenge

Find a manufacturing partner who can provide the full capabilities and get the design from prototype to production.

Result

Finish the process from prototype to production in less than half a year.

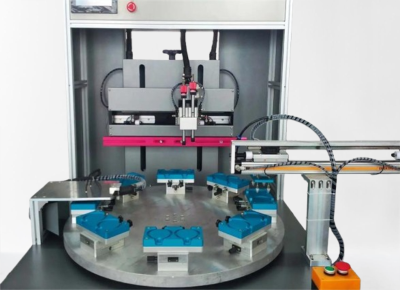

Injection Molding Work Process

At Xu Feng, we streamline your order process — from design files to quality-certified mold making and on-demand parts production. Our expert team and state-of-the-art machinery are dedicated to meeting your project needs efficiently

Upload 3D CAD and 2D technical drawings by email or send us a sample of the part with your detailed requirements.

Our engineering team will provide the price in 24 hrs followed by a free DFM including the mold flow analysis.

Our team will fully discuss the mold design drawings with you, and machine the tool strictly according to the drawings.

Free T1 samples will be provided within 2 weeks for your approval to ensure every detail aligns with your specifications.

Once samples are approved, we initiate full-scale production or arrange the tool packing according to your needs.

Tools in wooden or parts in cartons will be delivered according to your requirements, by air/sea or express.

You own the tools, we will keep them for at least five years, allowing you to reorder parts or relocate the tools as needed.

Have questions about injection molding? Our experienced team is ready to assist you and will respond within 24 hours.

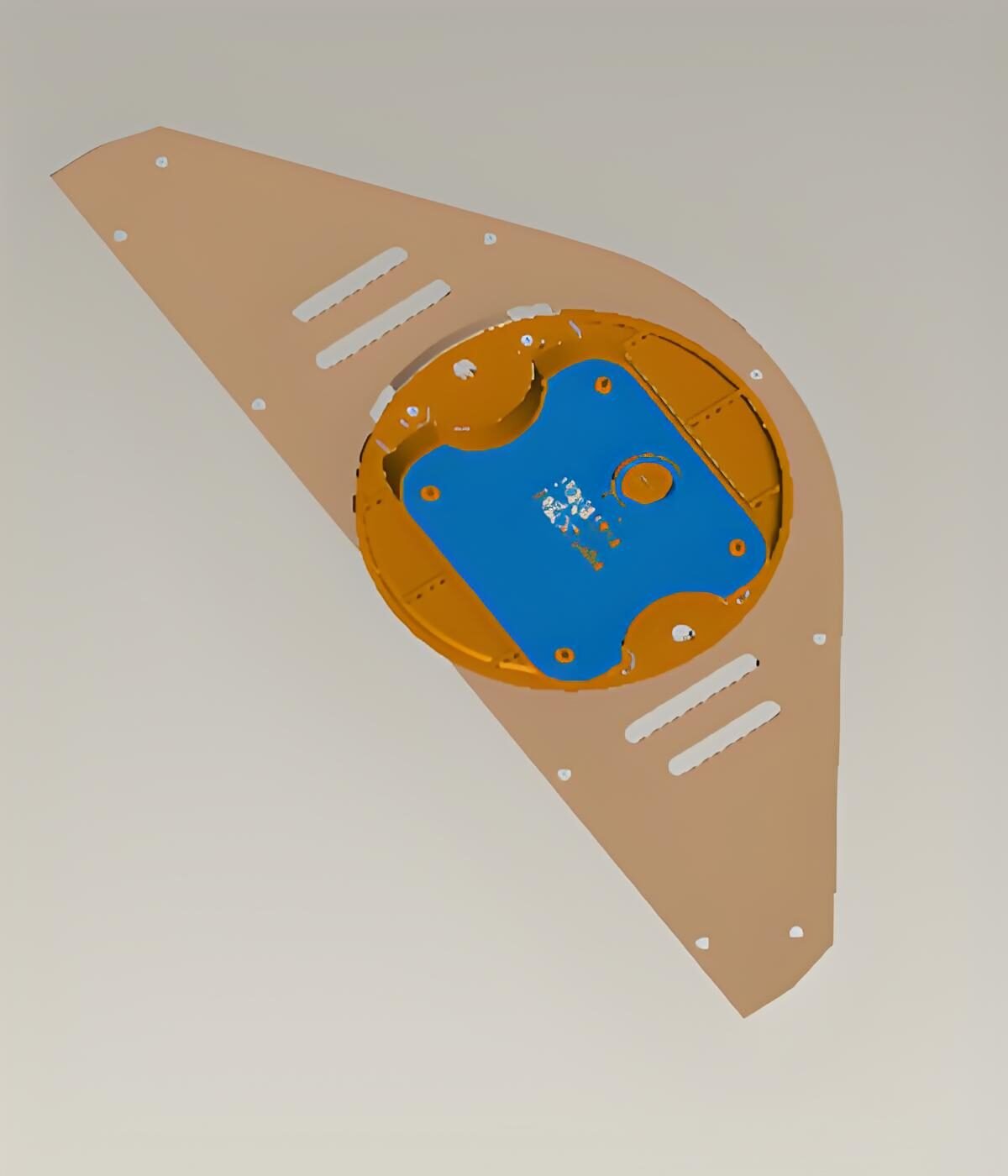

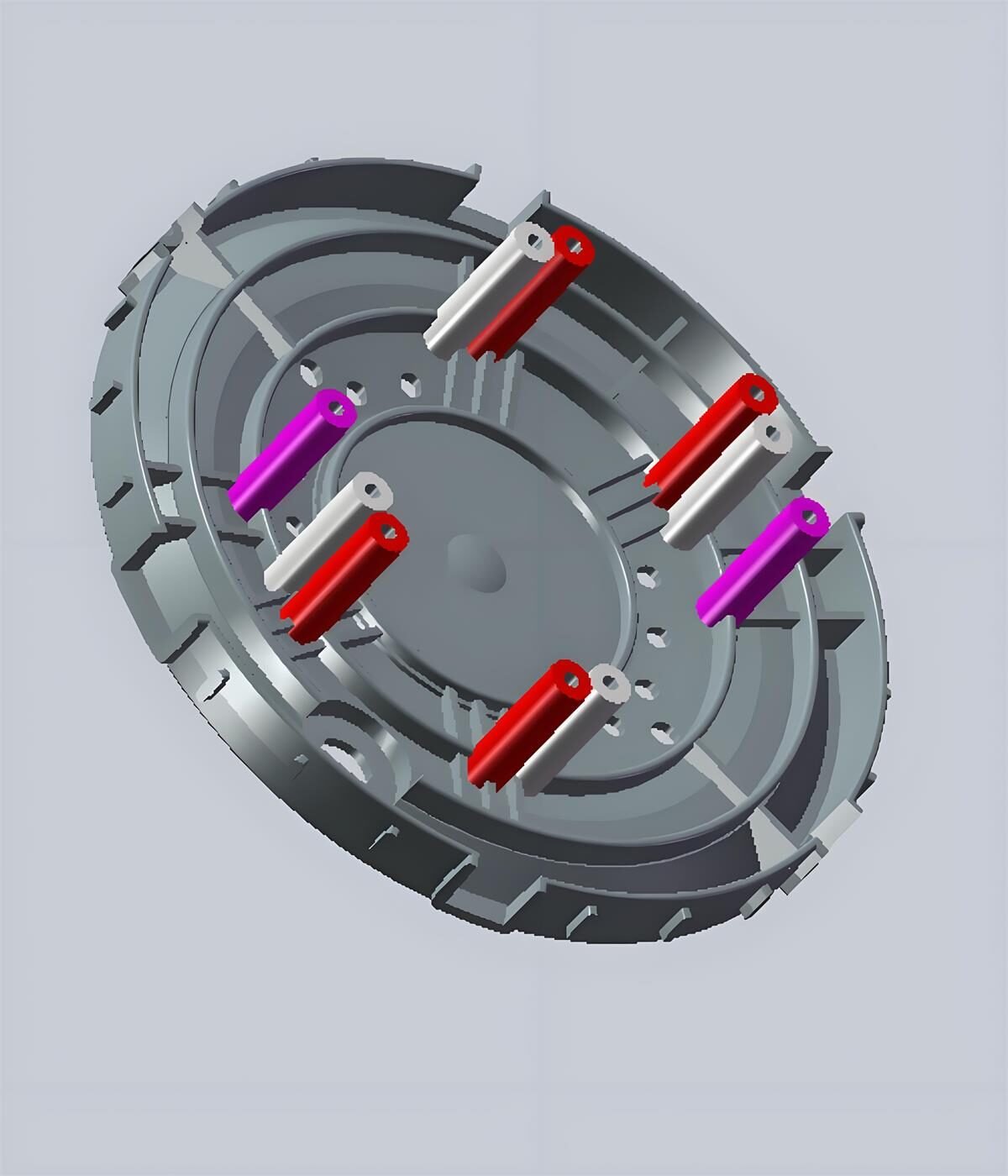

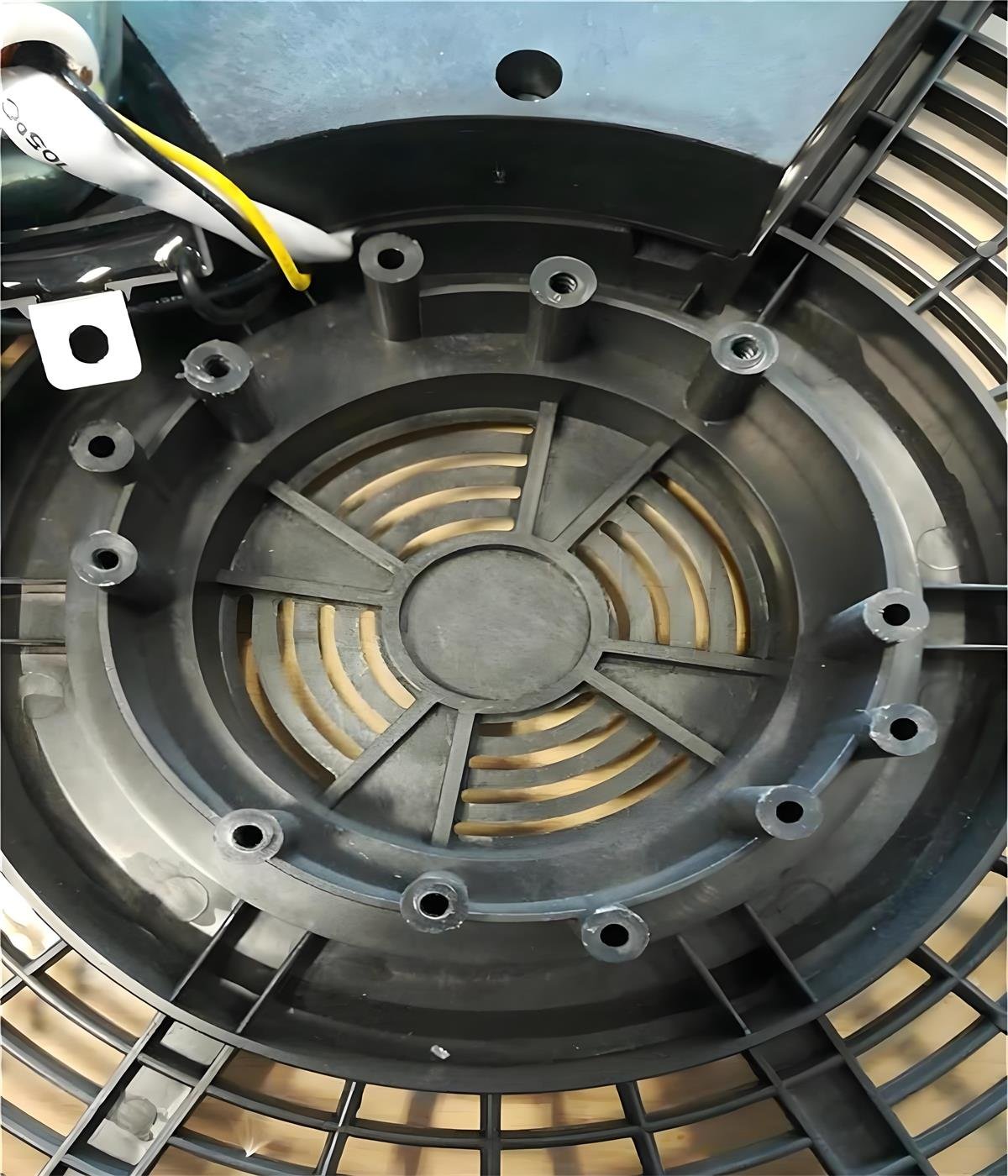

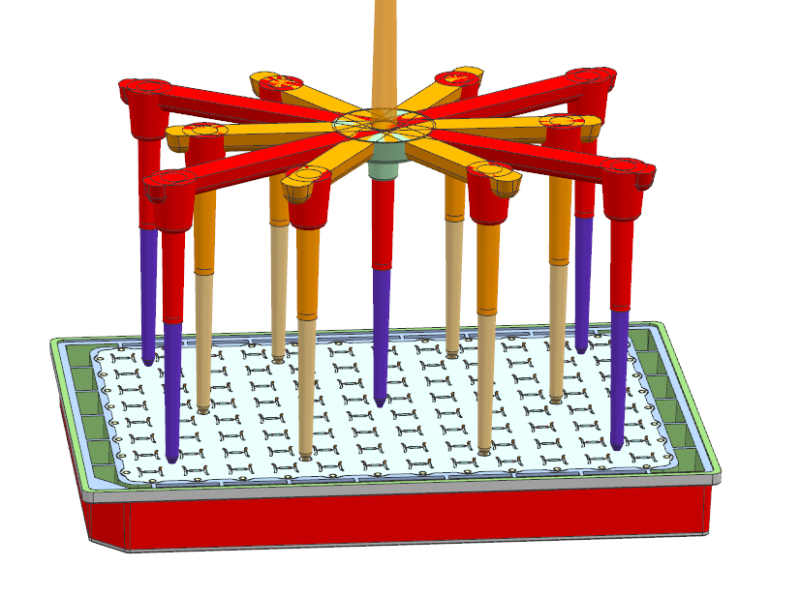

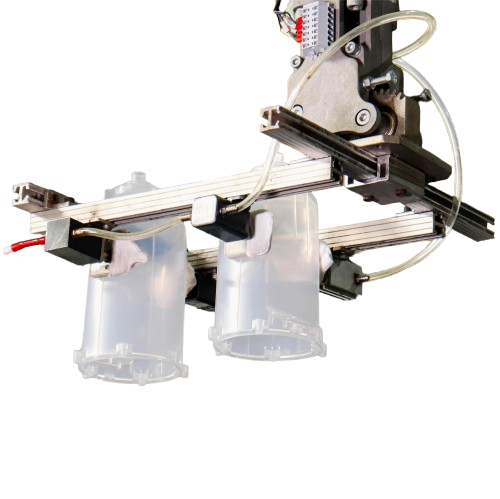

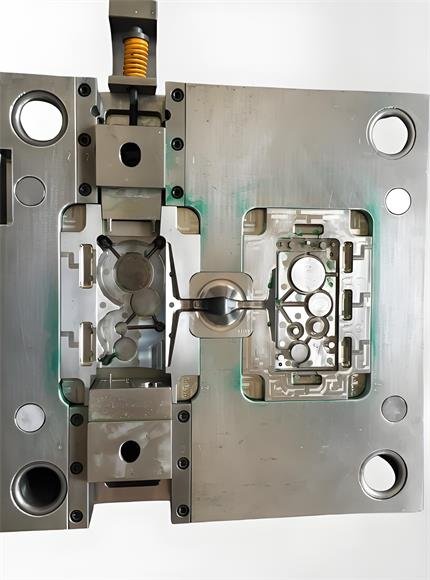

Injection Molding Parts and Tools Made By Xu Feng

Some custom injection prototypes, end-use parts and metal dies we’ve produced for our customers.

Let’s Creat Something Amazing, Together

Our latest news & blog

Quia pede? Debitis magna. Luctus itaque lectus, mi, veniam mollit minim aptent platea. Ducimus? Irure fusce, curabitur facilisis, recusandae sapiente pulvinar ullamco!

TD copper dies

About the team Industry: the tool for the wood industry

PHU Prototypes for Orthodontist

About Client Industry: Medical Devices Product: Prototypes for Orthodontist Location:

FMS Microfluidic board

About Client Industry: Medical Devices Product: Microfluidic Chip for devices