Xu Feng caters to custom requirements of prototypes and metal dies by utilizing simple tools and stamping processes, from concept to product.

01.

Rapid quotes in 24 hours

02.

Free DFM feedback

03.

Mechanical Assembly

04

10+materials and 7 finishes

Our Sheet Metal Services

Laser cutting

Using a high-powered and focused laser beam creates precise cuts in sheet metal materials.

Bending

Shapes flat sheet metal into V, U, or channel forms by using a press brake or custom dies.

Stamping

Forming a piece of sheet metal into a desired shape or configuration using a stamping press and dies.

Assemblies

Welding, riveting and surface finishing are available secondary sheet metal processes in Xu Feng.

Sheet Metal materials

The choice of an aluminum alloy for sheet metal fabrication depends heavily on the specific requirements of the project, For example, for marine environments, Alloy 5052 is preferred for its corrosion resistance, while for structural applications requiring high strength, Alloy 2024 or 6061 might be chosen.

Al 6061

Al 5052-H32

Al 2024

Al7075

When selecting a stainless steel for sheet metal fabrication, consider corrosion resistance, formability, strength requirements and aesthetic. choosing the right grade according to your requirements.

SS316

SS301

SS304

SS303

SS430

Steel is widly used for sheet metal due to its cost-effectiveness, good machinability, high strength, and versatile heat treatment methods. However, it often requires surface treatment to prevent rusting. At Xu Feng, we offer various surface treatments to address this need.

Carbon Steel DC01, 1018, 1020

Galvanized Steel

Cold Rolled Steel

Hot Rolled Steel

The choice of brass type depends on your specific requirements, including environmental exposure, mechanical stresses, and aesthetic needs. For example, if your product is exposed to seawater or where extra strength is needed, then C46400 is ideal.

C27000(H62)

C46400(HSn62-1)

C36000(HPb63-3)

Copper is a highly versatile metal known for its excellent electrical and thermal conductivity, making it a preferred choice for metal sheets in various industrial applications. For example, ETP is widely used in electrical applications for its high electrical and thermal conductivity and good corrosion resistance.

C11000(ETP, T2)

C10100(OFHC)

C12200(DHP)

* For materials not shown here, please get in touch with us directly

Sheet Metal Finishing Options

Powder Coating

Powder coating applies a dry powder to the surface of sheet metal parts. Then, they are cured in a large oven to create a hard finish that is tougher than conventional paint.

- 10+ colours can be chosen

- Various texture and gloss levels are available.

Plating

Plating (or coating) available plating options include:

- Anodize (type II or type III)

- Zinc

- Passivate

- Chromate

- Electroless Nickel

- Tin

Engraving

This process is often used for adding labels, instructions, or decorative patterns to fabricated metal products.

Available plating options include:

- Laser engraving

- Silk Screening

- Stamping

Download our Sheet Metal Design Guide

Check out our sheet metal design guide for a quick snapshot of various sheet metal materials.

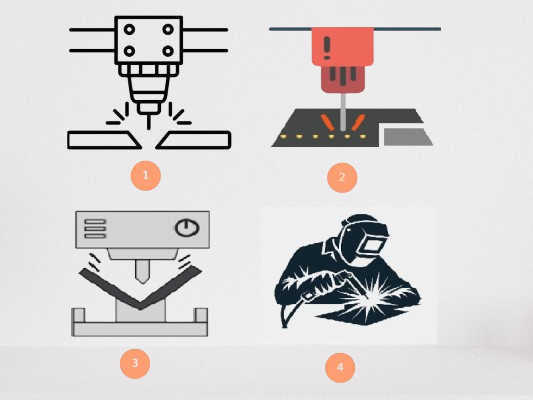

How Does Sheet Metal Fabrication Work?

There are generally four steps in sheet metal fabrication:

- Thin metal sheets are first precisely cut into smaller pieces according to programmed designs.

- A sheet metal punch is employed to add distinct features for parts requiring additional detailing.

- The pieces are then moved to a press brake, bent and shaped into their final forms.

- Often, secondary operations such as painting or welding are applied to enhance the finished metal parts.

Advantages of Sheet Metal Fabrication

The sheet metal fabrication process is ideal for metal components and can support both prototyping and production quantities.

- Low material waste and quick turnaround, a simple prototype can be provided within 3 days.

- Can cost-effectively scale to production volumes.

- Multiple finishing options like anodizing and powder coating.

- Often designed to be integrated with other manufacturing processes.

Sheet Metal Fabrication Service in Xu Feng

At Xu Feng, we offer two tailored solutions for your metal sheet requirements:

For Simple, Small-Scale Projects: We use straightforward tools

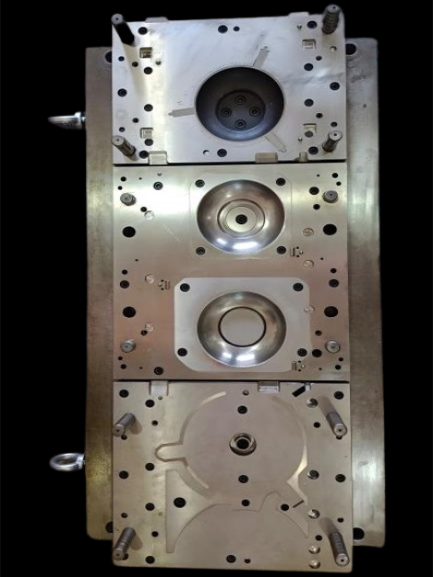

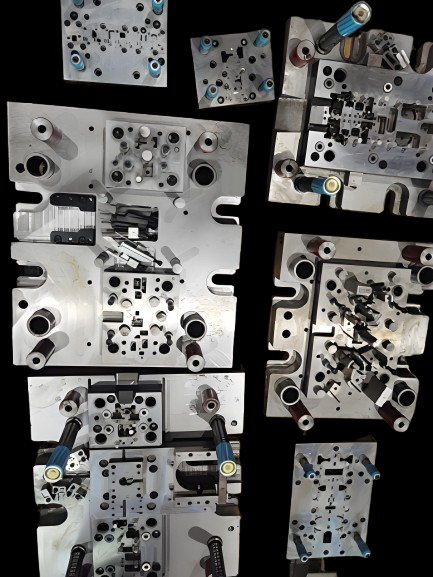

For Large-Scale Production: We craft custom metal dies, ranging from simple punch dies to complex progressive dies.

Sheet Metal Capability and Lead Time Map

Fabrication Capabilities

- Laser Cutting

- Deburring

- Punching

- Bending

- Hardware insertion

- Tapping

- countersinks

Volume

- Prototyping

- Low-volume

1-10 pieces

Tolerance

- Material thickness

≤0.236 in. (≤6mm)

- Linear Dimension

±0.004in.(±0.1mm)

- Bending Radius

1-3 times sheet thickness

Applications

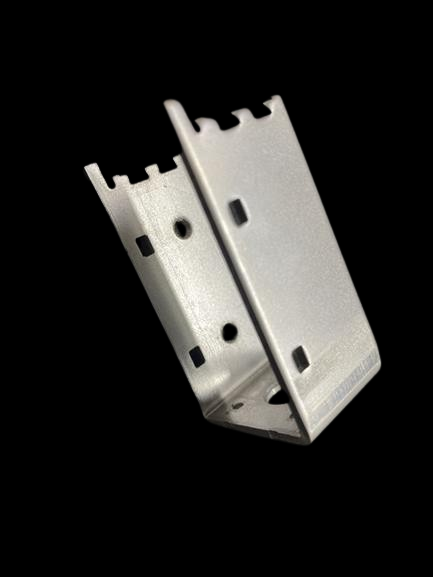

- Flat geometries

- Brackets

- Covers

- Panels

- Mounts

Fabrication Capabilities

- Single punching die for Punch-formed features

- Progressive die for complex sequencing or setups

- Integrated with post-machining( slots, pockets, or complex contours)

- Intricately formed features(hems, curl, stretch)

Volume

- single punching component

≥500 pieces

- two or more steps component

≥100 pcs

Tolerance

- Material thickness

0.002 in. – 0.250 in.

(0.05mm-6.35mm)

- Linear Dimension

±0.004in.(±0.1mm)

- Hole

±0.0008in.(±0.02mm )

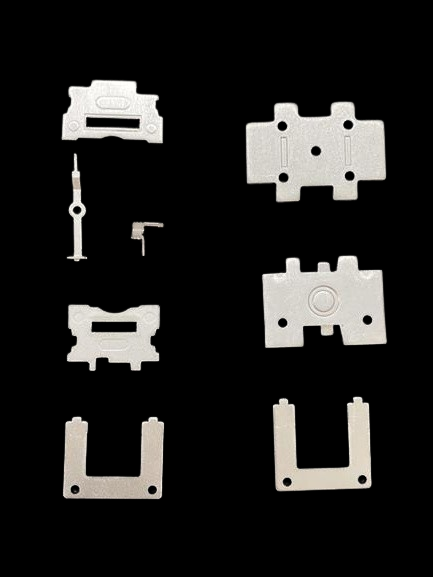

Applications

- Enclosure or chassis housings

- Electronic components

- Terminal connectors

- Auto Accessories

- Gear Box Accessories

- Complex internal componentry

Fabrication Capabilities

- Welding(add 2 days)

- Riveting(add 1 days)

- Assembly(add 2-3 days)

Finishing Options

- Powder Coating (add 2 days)

- Plating/coating (add 2 days)

- Masking (add 1-2 days)

- Engraving (add 1 day)

Applications

- Weldments

- Multi-component assemblies

- End-user-facing product

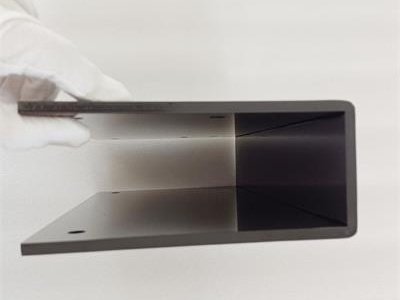

Sheet Metal Parts and Tools Made By Xu Feng

Some custom metal sheet prototypes, end-use parts and metal dies we’ve produced for our customers